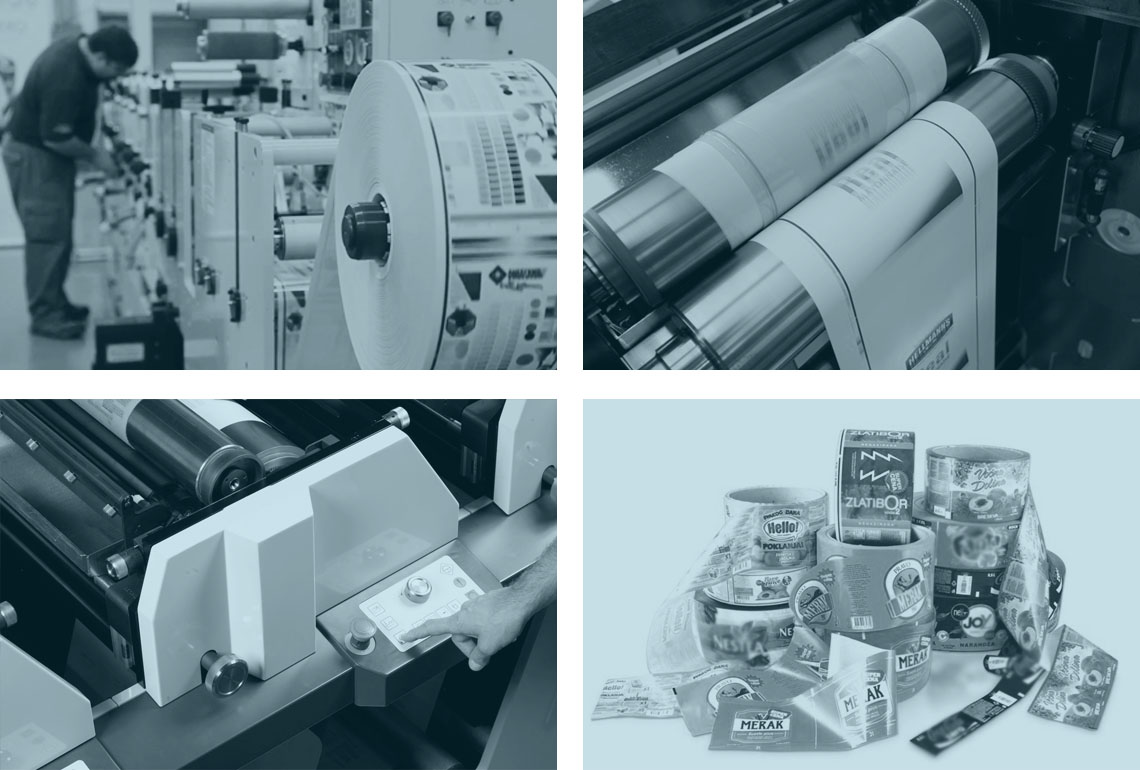

Print technology

During the printing process a flexible relief plate is utilized, which is most suitable for mass production. A mock model is transferred on the product using elastic photo polymer, and the final result is of very high quality and with rich colors.

Advantages of flexographic printing

This printing technique ensures quick and effective manufacturing which allows reducing the cost. Flexographic print is characterized by high print quality and an ability to transfer the desired design on various surfaces (paper, pvc, foil). The possibility to use CMYK and Pantone colors allows providing accurate colors and high quality images.

Usage of Flexography

This printing technique suits for commercial printing, for products that have an arched and flexible surface, for example, labels or stickers.

One of the most popular flexographic products are “flowpack” type packaging used for food. Flexographic printing technique enables printing not only on sticky products, but also on transparent polypropylene sheet, which can be used for labels and “flopack” type packaging.

Free consultation

Do you struggle choosing which printing technique is the best for you? Want an advice from a professional? Contact us and we will provide you with consultations free of charge.